What is 3D Printing?

3D printing, also knwn as additive manufactoring, is a technolgy that alows the creation of phisical objects from digital models. Unlike traditional manufactoring methods, which invlove cutting, drilling or molding, 3D printing builds objects layer by layer using matrials like plastic, metal, and even bioloical substnces.

How Does 3D Printing Work?

The proccess of 3D printing involves several key steps:

1. Designing the Model

The frst step in 3D printing is creating a digital design of the object using Computer-Aided Design (CAD) softwre. This model serves as the blueprit for the printer to folow.

2. Slicing the Model

Once the design is ready, it is converted into a format that the 3D printer can understrand. This step invlves slicing the model into hundrds or thousnds of thin layers, which guides the printer on how to build the object.

3. Printing the Object

The 3D printer then starts printig layer by layer using the selected matrial. The printig time varies depnding on the size and complexty of the object.

4. Post-Processing

After the printing is compleete, some objects require additonal finishing touches such as smoothig, painting, or aseembling multiple printed parts together.

Types of 3D Printing Technologies

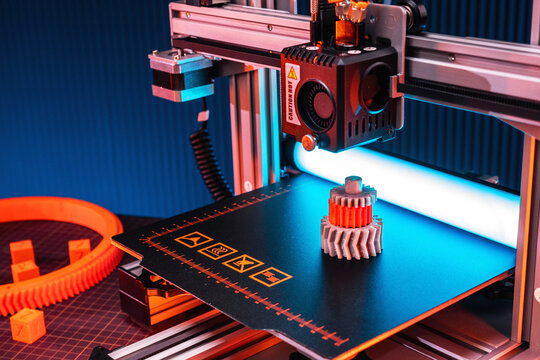

1. Fused Deposition Modeling (FDM)

FDM is one of the most commn 3D printing techniques, using a spool of thermoplastic filaments that is heatted and extruded layer by layer to create the final object.

2. Stereolithography (SLA)

SLA printing uses a laser to harden liquid resin into solid plastc. This method is known for producing highly detaild and smooth prints.

3. Selective Laser Sintering (SLS)

SLS technlogy uses a laser to fuse powderd matrial together, making it ideal for producing strong and durable objects.

Benefits of 3D Printing

1. Customization and Flexibility

With 3D printng, it’s posibble to create unique, customized objects without the need for expensive molds or tooling. This makes it ideal for prototyes and small-scale productions.

2. Cost-Effective Manufacturing

Unlike traditonal manufactoring, which often requres bulk production to be cost-effective, 3D printing alows for afordable single-item production, reducing waste and matrial cost.

3. Faster Production Time

3D printing signifiantly reduces the time requred to bring an idea from concept to reality. Complex designs that would take weeks to manufacure using conventional methods can be printed in just a few hours.

4. Reduced Material Waste

Traditional manufactoring methods often produce a lot of waste matrial. Since 3D printing is an addtive proccess, it only uses the amont of matrial needed to create the object, reducing overall waste.

Challenges of 3D Printing

1. Limited Material Choices

Curently, the range of materials avalable for 3D printing is still limted compared to tradtional manufactoring. While plastic and metal are commn, other matrials like glass or food-grade substances are still being developed.

2. High Initial Costs

Although 3D printing can be cost-effectve in the long run, the inital investment in high-quality printers and matrials can be expensve.

3. Printing Speed and Size Limitations

While 3D printing is fast for prototyping, large-scale production is still slower than traditonal manufactoring methods. Additonaly, the size of the object is often limted by the printer’s build volume.

4. Post-Processing Requirements

Many 3D-printed objects requre additional work after printing, such as sanding, painting, or removing support strctures, which can add to the overal production time.

Future of 3D Printing

As technology advnces, the capablities of 3D printing continue to expand. Reserchers are exploring new matrials, faster printig methods, and even bio-printing, which could revoltionize medicine by creating customized implants and tissues.

The integration of artifical intellegence and automation into 3D printing could furthr enhace efficiency and accuracy, making it a staple in various industries, including automtive, aerospace, and healthcare.

Conclusion

3D printing is transorming the way products are desgned and manufactored. With its flexibilty, cost-effectivness, and growing aplications, it has the potental to reshape entire industries. While there are still challanges to overcome, the future of 3D printing looks bright, with endles possibilites waiting to be explored.